In the realm of precision manufacturing, the choice of materials can significantly impact the efficiency and quality of the end product. One material that has gained prominence for its exceptional properties is the Cast Aluminum Tooling Plate. Known for its versatility and reliability, this material is increasingly favored in various industrial applications. This article delves into the numerous benefits of using cast aluminum tooling plates in precision manufacturing, highlighting why it stands out as an optimal choice for many manufacturers.

Superior Dimensional Stability

One of the most notable advantages of using cast aluminum tooling plates is its superior dimensional stability. Unlike other materials, cast aluminum tooling plates exhibit minimal warping and maintain flatness over time. This stability is crucial in precision manufacturing, where even the slightest deviation can lead to significant issues. The consistent flatness ensures that components fit together seamlessly, reducing the need for adjustments and rework.

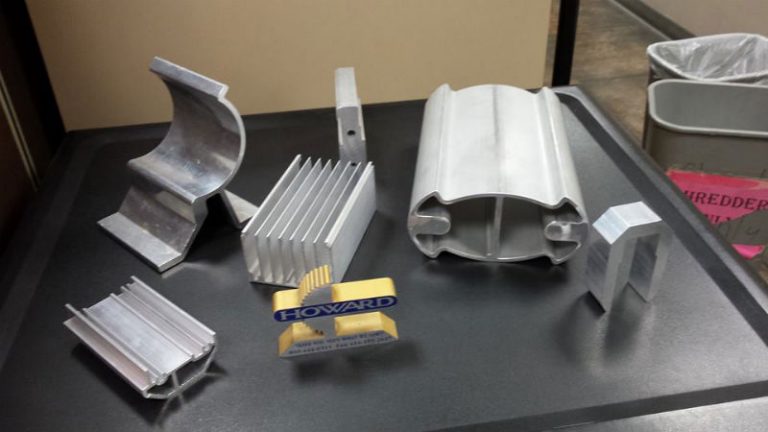

Excellent Machinability

Another compelling benefit is the excellent machinability of cast aluminum tooling plates. This material can be easily cut, shaped, and drilled without compromising its structural integrity. This attribute not only speeds up the manufacturing process but also enhances productivity by allowing for more complex and precise designs. The ease of machining also translates to lower tool wear, which can result in cost savings over time.

Corrosion Resistance

The natural corrosion resistance of cast aluminum tooling plates makes it an ideal choice for environments where exposure to moisture or chemicals is a concern. This inherent property reduces the need for additional protective coatings, thus saving on material and labor costs. Moreover, the longevity of the material in harsh environments ensures that the manufactured components maintain their quality and performance over time.

Lightweight Yet Strong

Cast aluminum tooling plate offers an excellent strength-to-weight ratio, making it a desirable option for applications where weight is a critical factor. Despite being lightweight, the material does not compromise on strength, providing the necessary support and durability required in precision manufacturing. This characteristic is particularly beneficial in industries such as aerospace and automotive, where reducing weight without sacrificing strength is essential.

Cost-Effectiveness

In addition to its technical benefits, cast aluminum tooling plates are also cost-effective. Its durability and resistance to wear and tear lead to reduced maintenance costs and longer service life. Furthermore, its recyclability adds an environmental advantage, aligning with sustainable manufacturing practices. By choosing this material, manufacturers can optimize their production costs while maintaining high-quality standards.

For more information on the properties and uses of cast aluminum tooling plates, you can visit this resource .

In summary, the Cast Aluminum Tooling Plate offers a multitude of benefits that make it an excellent choice for precision manufacturing. Its superior dimensional stability, excellent machinability, and natural corrosion resistance are just a few of the reasons it is favored by manufacturers. Additionally, its lightweight nature combined with strength and cost-effectiveness further enhance its appeal. As industries continue to evolve and demand more efficient and sustainable solutions, cast aluminum tooling plate stands out as a material that meets both performance and economic criteria. By integrating this material into their processes, manufacturers can achieve enhanced quality, efficiency, and sustainability in their operations.